E-mail seo@sino-purification.com

Time:2025-09-28 11:55:38 Reading volume:

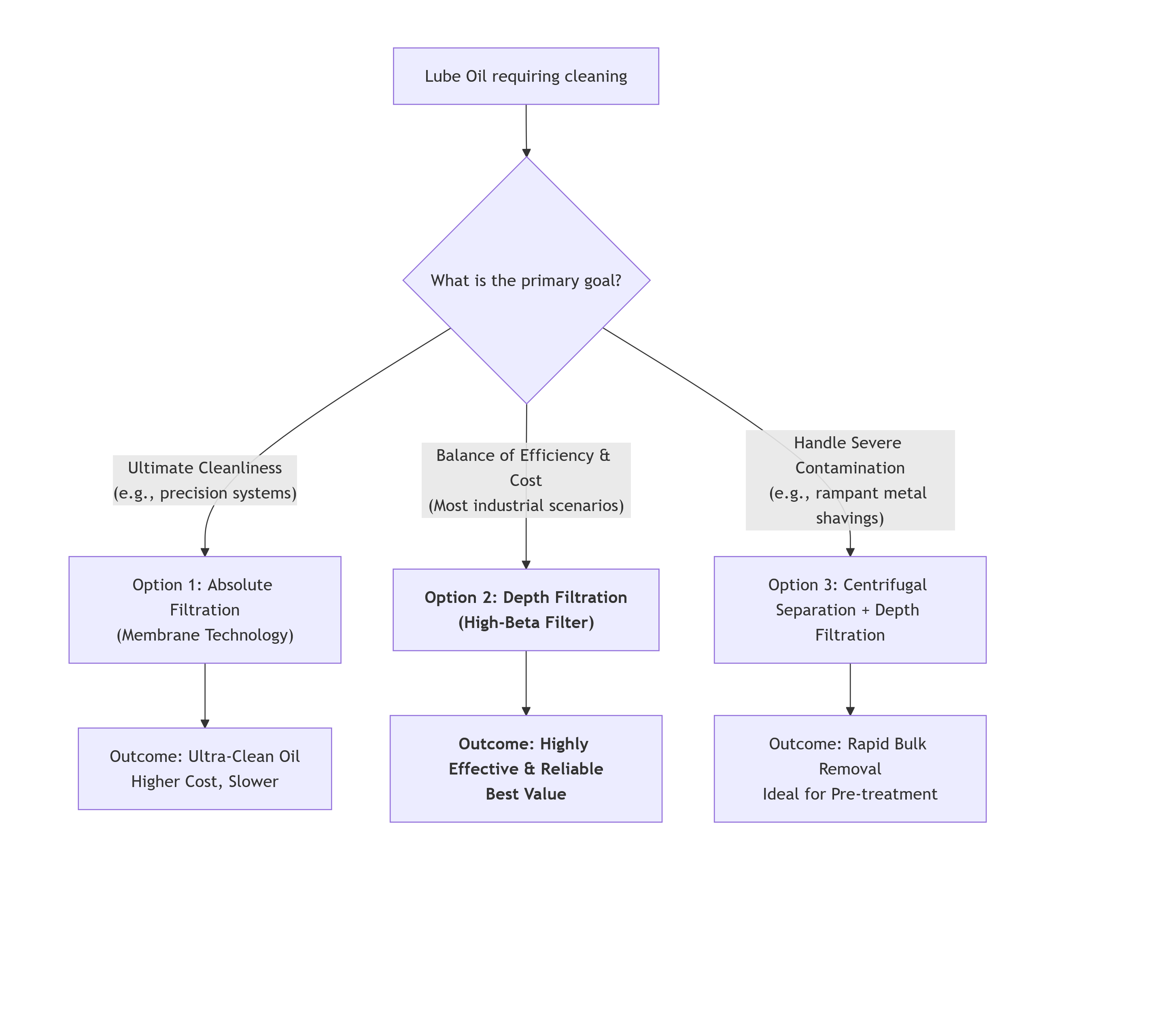

Learn the most effective methods for removing solid contaminants from lubricating oil. Explore depth filtration, absolute filtration, and centrifugal separation to achieve reliable oil cleanliness and protect equipment.

Introduction

Contaminants in lubricating oil are one of the leading causes of equipment wear, premature failure, and costly downtime. Removing particles from oil is not just good maintenance—it is essential for reliability and operational efficiency.

The good news: oil filtration technology is mature, highly effective, and extremely reliable when applied correctly. While there is no single “best” method for all situations, there is always a best-fit solution tailored to your cleanliness targets, equipment requirements, and budget.

This guide outlines the three main methods of solid contaminant removal, their strengths, and practical recommendations to help you select the right strategy.

Depth filtration forces oil through a porous, multi-layer medium (typically glass microfibers or cellulose). Particles are trapped within the depth of the media by adsorption and sieving.

Why It’s Reliable

Think of it as a multi-layer security system—it captures a wide range of particle sizes and offers a high dirt-holding capacity, meaning longer filter life and fewer replacements. It is the most widely used and cost-effective method for protecting pumps, bearings, hydraulic valves, and gears.

Key Metric

Choose filters with a high Beta Ratio (βₓ ≥ 200). This means the filter removes 99.5% of particles of a specified size (x µm), ensuring high efficiency.

Absolute filtration uses a membrane or precision screen with an exact pore size rating (e.g., 1 µm). All particles larger than the rating are retained.

Best For

Critical systems where even tiny particles cause major failures

Hydraulic servo controls

Aerospace applications

High-speed turbomachinery

Limitation

Absolute filters are highly precise but have lower dirt-holding capacity and are more expensive. They are often used as a final polishing stage after depth filtration.

A centrifuge spins contaminated oil at high speed. Heavier particles—such as sludge, metal shavings, or water droplets—are flung outward and collected on the bowl walls.

Best Role

Pre-treatment for heavily contaminated oils

Effective for large solids and high sludge loads

Requires no disposable filter media

Limitation

Centrifugal separation is ineffective against fine particles close in density to the oil. It is best used as a complementary method rather than a standalone solution.

Why Particle Removal Is Proven and Reliable

Technically Sound: Filtration is a well-understood process, validated by standards like ISO 16889, ensuring repeatable and measurable performance.

Economically Wise: The cost of filters and filtration services is negligible compared to equipment repair, downtime, or lost production.

Practically Verifiable: Portable particle counters provide instant ISO Cleanliness Codes (e.g., ISO 4406 16/14/11), giving you measurable proof of oil quality.

Define Your Target: Consult your equipment manual for the required ISO Cleanliness Level.

select the Right Tool: In most cases, a portable unit with depth filtration (βₓ ≥ 200) offers the most reliable and economical solution.

Operate Correctly: Monitor differential pressure (ΔP) across the filter. replace the element before the bypass valve activates. Running oil through a bypassed filter reintroduces contaminants into your machine.

Verify Results: Use a particle counter to confirm cleanliness before returning oil to service.

Conclusion

For the majority of industrial operations, depth filtration is the most reliable and cost-effective method for removing contaminants from lubricating oil. Supported by international standards and measurable data, it directly prevents wear, extends equipment life, and reduces maintenance costs.

Bottom line: effective oil contamination control is not an expense—it’s an investment in uptime, reliability, and profitability.

Root Causes of Loss of Control in Vacuum Oil Purification Systems

How Industrial Oil Filters Remove Water and Impurities: A Comparison of Technical Principles

How to Choose the Right Industrial Oil Purifier: A Comprehensive Buyer’s Guide

How to Choose the Right Oil Purifier for Different Oil Types?

Double-Stage Vacuum Pumping: The Complete Guide to Transformer Maintenance