E-mail seo@sino-purification.com

Time:2025-08-28 13:16:00 Reading volume:

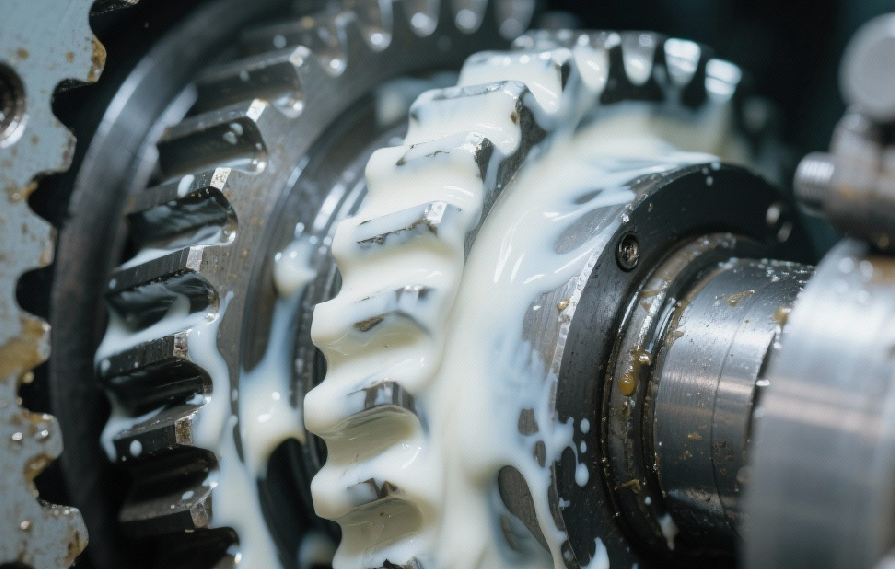

Preventing emulsification in industrial gear oil is vital for smooth equipment operation. Emulsification reduces lubrication, rust prevention, and cooling. This can increase gear wear, cause corrosion, and lead to equipment failure. You need a three-part approach: find the cause, act quickly, and check in often.

To tackle emulsification, understanding its causes is key. Three conditions must be met:

Base Oil + Emulsifier: Gear oil can mix with certain additives, like detergents.

Water: This is the main culprit. Sources include:

Condensate forms when the air in the tank cools after shutdown. This happens, especially during temperature changes.

Leaks: Water may enter through damaged cooler pipes or poor seals during flushing.

Ambient Humidity: In humid areas, moisture can enter through the breather valve.

Gears mix oil and water with great intensity during operation. This creates tiny droplets that are difficult to separate.

To stop emulsification, get rid of moisture sources. Also, remove any water that gets in right away.

This approach is efficient and cost-effective.

Fuel Tank Seals and Breathing Valve (Air Filter): Regularly check the breathing valve. replace the desiccant as needed. Ensure it filters moisture and impurities. In humid areas, consider using a dryer for dry air.

Seal Inspection: Check seals on windows, port covers, level gauges, and sensor connectors regularly. This helps keep moisture out.

Control Oil Temperature: Verify that heaters and coolers operate effectively. Keep oil above the dew point when equipment is off to prevent condensation. During operation, ensure the cooler works to avoid temperature swings.

Standardize Operations: Avoid direct flushing with water. If you need to clean, use waterproof bearings and seals. During maintenance, cover open oil tanks if it’s rainy or humid.

Oil Storage: New oil can contain water! Store drums indoors and tightly sealed. Use clean tools for refueling.

Even with great prevention, water intrusion can still occur. Regular monitoring is essential.

Regular Oil Analysis: This is the best early warning method. Test the water content by sampling oil regularly. If levels exceed 500 ppm, investigate. Comprehensive tests also check viscosity, acid value, and wear metals. A viscosity increase often signals emulsification.

Use high-quality oil: Choose gear oil with good demulsification properties. Quality lubricants quickly separate water, allowing it to drain.

Prompt Drainage: Most tanks have a drain valve at the bottom. Open it every week to remove settled water and impurities. For critical equipment, install an automatic drain for when water accumulates.

Silent Sedimentation: Let the equipment sit to allow water to settle, then drain it.

Centrifugal Oil-Water Separator: Use special equipment to separate water when levels rise.

replace the Oil: If the oil looks milky or creamy, it’s time to replace it. Clean the gearbox too. Residual emulsion can contaminate new oil.

Preventing gear oil emulsification requires systematic maintenance, not just reactive fixes. This strategy can greatly reduce risks and ensure stable equipment operation.