E-mail seo@sino-purification.com

Time:2025-10-10 14:07:01 Reading volume:

Why Regular Insulating Oil Purification Is Critical for Transformer Reliability

Regular purification and filtration of insulating oil are crucial for ensuring transformer safety, reliability, and extended service life. Learn how moisture, sludge, and oxidation damage transformer insulation—and how purification prevents costly failures.

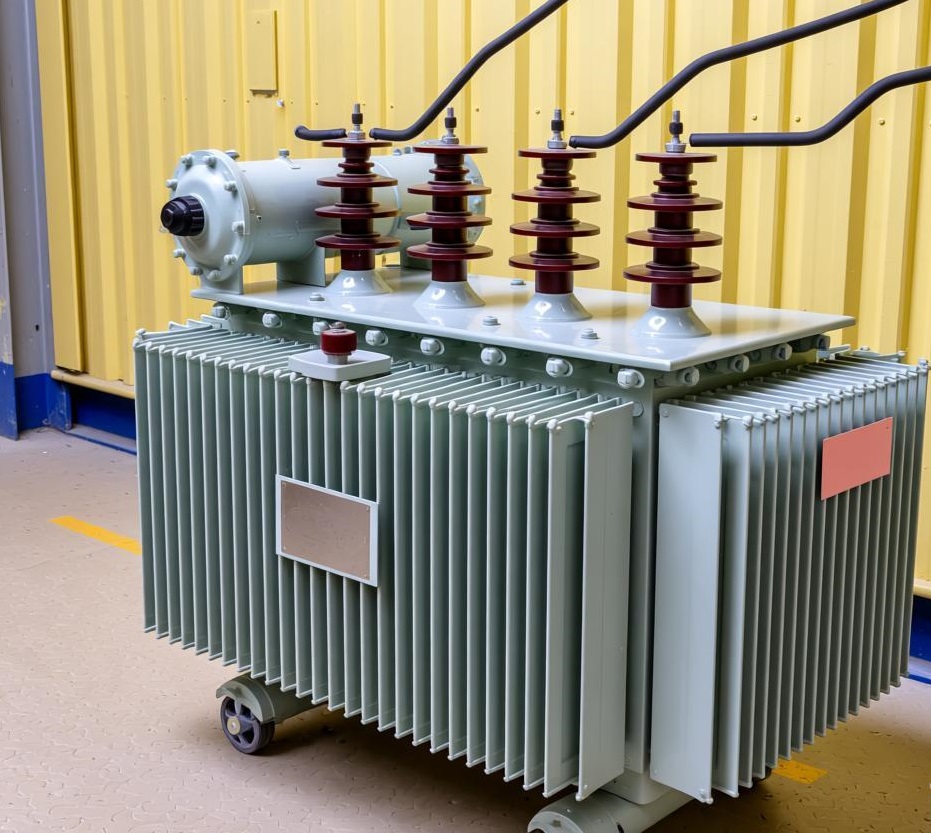

Insulating oil—often called the “blood” of transformers and power equipment—performs two vital functions: electrical insulation and cooling.

Just as impure blood leads to illness, contaminated insulating oil can cause severe equipment malfunctions or even sudden failure. Maintaining clean, stable oil is therefore crucial for safe operation and a prolonged service life.

Moisture Intrusion – The #1 Enemy

During normal operation, transformers “breathe” as they heat and cool. This process allows moisture from the air to enter the oil. Additionally, aging of internal solid insulation materials (such as paper and wood) can generate water internally.

Even small amounts of moisture can drastically reduce the oil’s dielectric strength (breakdown voltage), increase the risk of partial discharge or arcing, and accelerate insulation failure.

Solid Impurity Contamination

Metal particles, carbon (from arcing), and fibers suspended in oil can form conductive “bridges” under electric fields. These create leakage paths that significantly weaken insulation and increase the likelihood of dielectric breakdown.

Transformers generate substantial heat during operation, and oil circulation is the primary means of removing this heat.

However, as oil ages under high temperature and oxygen, it forms sludge and insoluble impurities. These deposits on the windings, core, and radiators form a heat-insulating layer. The result:

Reduced heat dissipation efficiency

Elevated winding temperature

Accelerated insulation aging

This vicious cycle can quickly lead to overheating, insulation degradation, and premature transformer failure.

The Oxidation Process

When exposed to oxygen and high temperatures, insulating oil gradually oxidizes, producing organic acids, alcohols, and sludge. These by-products not only darken the oil but also reduce its dielectric properties and stability.

How Purification Helps

Through vacuum dehydration and degassing, purification removes dissolved oxygen and moisture, effectively slowing down the oxidation rate. This significantly extends both oil and equipment service life, reducing the need for costly replacements.

Solid insulation components such as paper and pressboard are vital to transformer longevity—and are often more fragile than the oil itself.

Acidic by-products from oil oxidation can:

Corrode metallic components

Degrade cellulose insulation, reducing polymerization and mechanical strength

Lead to embrittlement, one of the main causes of transformer end-of-life

Regular oil purification removes acidic contaminants, protecting solid insulation and maintaining mechanical and dielectric integrity.

Modern transformer monitoring relies heavily on DGA (Dissolved Gas Analysis) to detect early-stage faults such as overheating, arcing, or insulation breakdown.

If the insulating oil is contaminated or degraded, the background gas and impurity levels can:

Distort DGA test results

Causes misdiagnosis or missed diagnosis

Delay necessary maintenance

Therefore, oil purity is the foundation of accurate transformer condition assessment and preventive maintenance.

Summary: Prevention Is Better Than Repair

Regular purification and filtration of insulating oil are not just maintenance tasks—they are preventive health care for power equipment. The process removes contaminants, restores dielectric and cooling properties, and slows down oil aging.

✅ Maintains dielectric strength and insulation integrity

✅ Improves cooling performance and thermal stability

✅ Reduces oxidation and acid formation

✅ Protects solid insulation materials

✅ Ensures reliable diagnostic test results

✅ Prevents unplanned outages and catastrophic failures

In practice, purification should be combined with routine oil testing—measuring breakdown voltage, moisture content, dielectric loss, and gas content—to determine the timing and extent of treatment.

Ultimately, the cost of purification is minimal compared to the economic and safety risks of equipment failure, unplanned power outages, or transformer explosions caused by deteriorated oil.

Root Causes of Transformer Sludge Formation: A Technical Analysis

Root Causes of Loss of Control in Vacuum Oil Purification Systems

How Industrial Oil Filters Remove Water and Impurities: A Comparison of Technical Principles

How to Choose the Right Industrial Oil Purifier: A Comprehensive Buyer’s Guide

How to Choose the Right Oil Purifier for Different Oil Types?