E-mail seo@sino-purification.com

Time:2025-05-16 11:31:14 Reading volume:

Acetylene (C₂H₂) in transformer oil cannot be directly removed by conventional physical filtration (such as filter elements, centrifuges, etc.) because acetylene is a gas dissolved in the oil, not a solid particle or liquid contaminant. However, it can be treated by the following methods:

- Causes:

- Discharge inside the transformer (local overheating, arcing) causes oil decomposition.

- Pyrolysis of insulating materials (such as cellulose aging).

- Risks:

- Acetylene is a fault indicator gas (C₂H₂>1ppm in DGA analysis requires vigilance).

- It may indicate serious discharge faults (such as winding short circuit, contact arcing).

(1) Vacuum degassing method

- Principle:

The dissolved gas is precipitated through high vacuum (≤0.1kPa) and heating (50~70℃).

- Effect:

- 80%~90% of acetylene can be removed (multi-stage vacuum pump is required).

- Equipment example: Pullman Holt vacuum oil filter (integrated degassing module).

(2) Adsorption method

- Materials:

- Activated alumina, molecular sieve (such as type 4A).

- Limitations:

- It may adsorb additives in the oil and antioxidants need to be added later.

(3) Oil change

- Applicable scenarios:

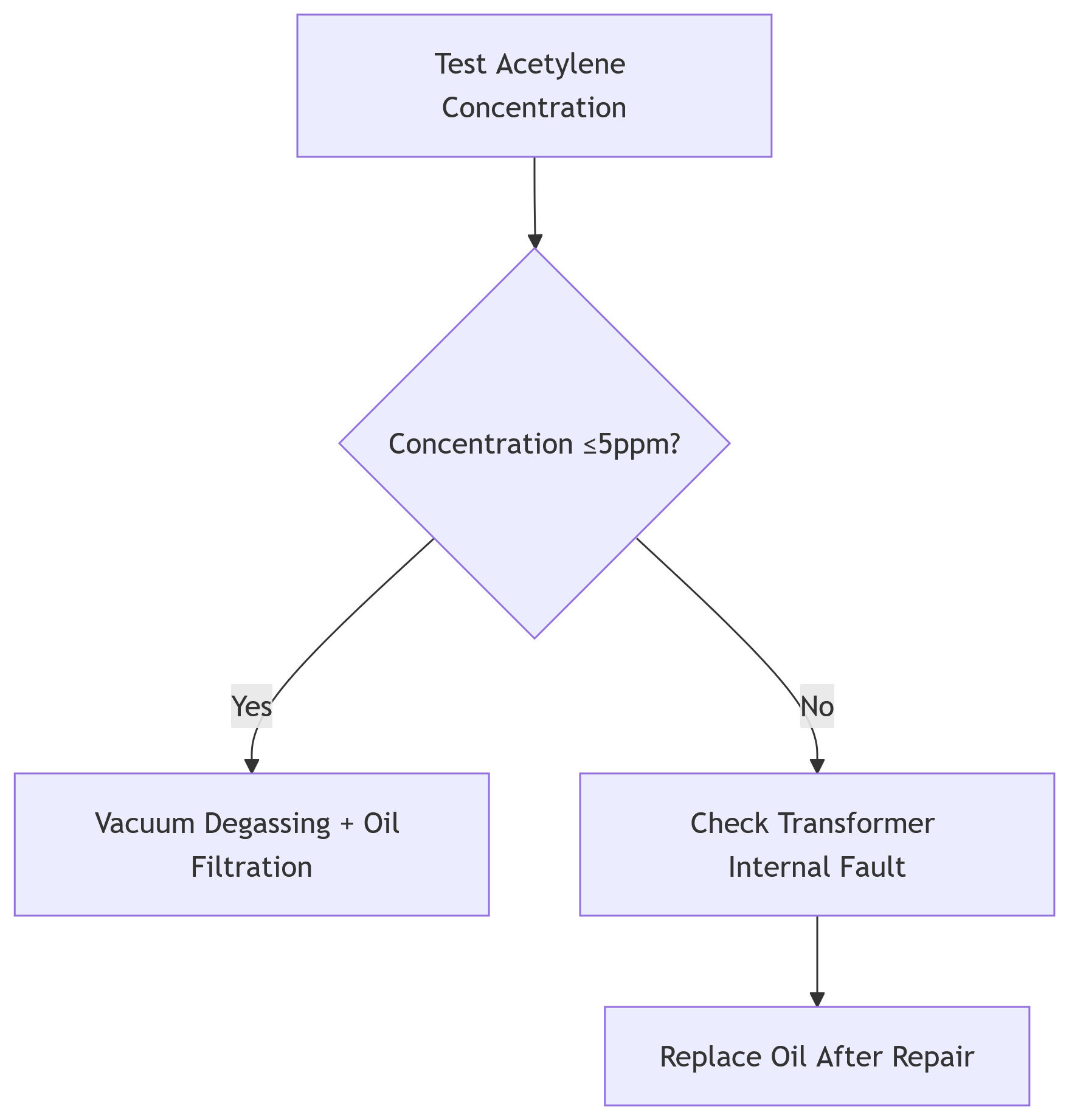

- Acetylene concentration is extremely high (>10ppm) or accompanied by other fault gases (H₂, CH₄).

- Diagnosis first and then treatment:

- Confirm the source of acetylene through DGA (dissolved gas analysis) and eliminate internal faults (such as evaluation using the IEC 60599 standard).

- Vacuum degassing parameters:

- Vacuum degree <0.5kPa, oil temperature is controlled below 60℃ (to avoid oil oxidation).

- Risks of adsorbents:

- The compatibility of adsorbents with oil products (such as changes in acid value) needs to be tested.

- Online monitoring:

Install a DGA online monitor (such as Qualitrol DCMax) to track gas content in real time.

- Maintenance recommendations:

- Regularly check bushing contacts and on-load tap changers (OLTC) to reduce discharge sources.

- Vacuum degassing equipment:

- Transformer oil regeneration devices from Pall (USA) , SINO-NSH(China NSH).

- Adsorbent supplier:

- BASF (molecular sieve), Axens (activated alumina).

Acetylene needs to be treated by degassing or adsorption, but the fundamental solution requires troubleshooting of equipment failures. If the acetylene content in the oil continues to rise, the equipment should be shut down for maintenance immediately!