E-mail seo@sino-purification.com

Time:2025-09-29 13:20:55 Reading volume:

Transformer oil filtration standards represent a comprehensive framework of performance metrics rather than a single specification. These standards are critical for maintaining dielectric strength and ensuring the long-term reliability of power transformers.

Below is a detailed analysis of international filtration standards, key parameters, and their practical application.

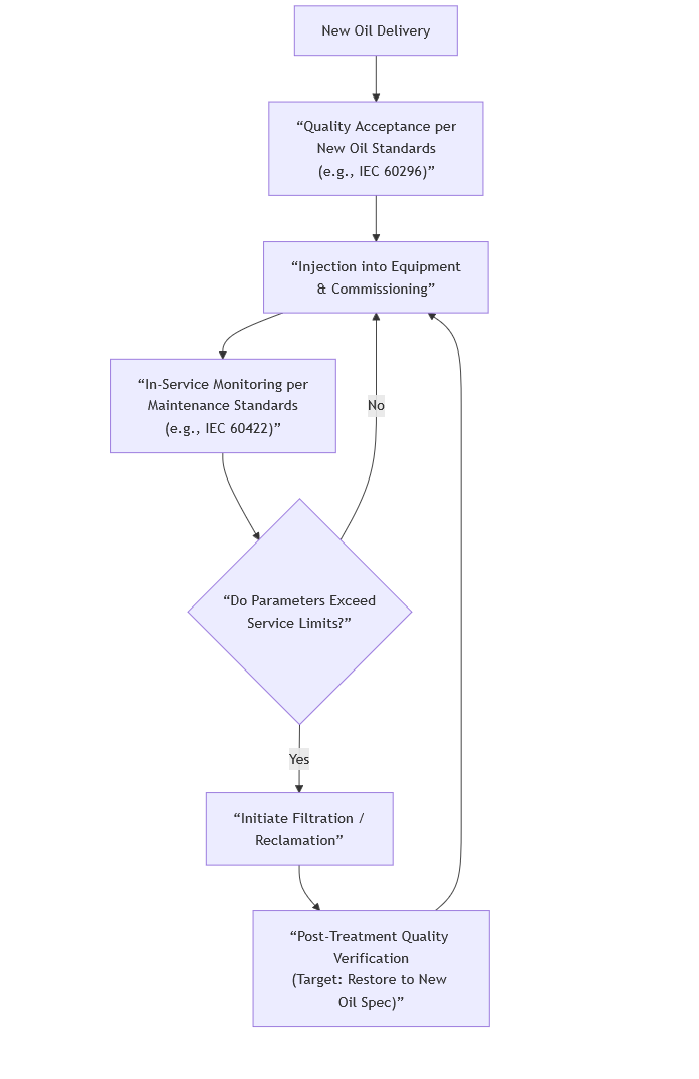

The entire lifecycle of transformer oil - from initial introduction to ongoing maintenance - is governed by a rigorous quality control process, as illustrated below:

2.1. Water Content (ppm)

- Criticality: Primary agent that degrades dielectric strength and accelerates oil aging.

- Target Values:

- New/Filtered Oil: ≤ 10 - 15 ppm (IEC 60422)

- In-Service Alert Level: ≤ 35 ppm (≤ 25 ppm for 330kV and above)

2.2. Dielectric Strength (Breakdown Voltage)

- Criticality: Direct measure of oil's ability to withstand high voltage stress.

- Target Values:

- New/Filtered Oil: ≥ 60 kV (IEC 60156)

- In-Service Minimum: ≥ 45-50 kV (higher for increased voltage classes)

2.3. Particle Count (Cleanliness)

- Criticality: Particles can abrade insulation and form conductive bridges, initiating partial discharge.

- Standards (NAS 1638 / ISO 4406):

- New/Filtered Oil: Typically ≤ NAS 1638 Class 6 or ISO 4406 15/13/10 (UHV transformers may require NAS Class 4).

- In-Service Control: ≤ NAS 1638 Class 8

2.4. Dissolved Gas Content

- Criticality: Liberated gases can form bubbles under thermal/load cycles, causing partial discharge.

- Target Values:

- New/Filtered Oil: ≤ 0.5% - 1%

- In-Service Alert Level: ≤ 3%

2.5. Dissipation Factor (tan δ)

- Criticality: Measures dielectric losses under AC voltage; high values indicate oxidation or contamination.

- Target Values (@ 90°C):

- New Oil: ≤ 0.005

- In-Service Oil: ≤ 0.04

| Scenario | Priority Parameters | Notes |

| | |

| New Oil Commissioning | Full compliance with new oil specs (IEC 60296) | Mandatory filtration before injection due to potential cont amination from storage/transfer. |

| Routine Maintenance | Restore moisture, dielectric strength, and cleanliness to near-new oil levels. | Preventive action when periodic testing shows minor devi ations. |

| Post-Major Repair | All parameters must meet new oil standards. | Necessary after core exposure to atmosphere, causing sig nificant contamination. |

| Post-Fault Conditioning | Full analysis plus acid number, metal content, and DGA. | Must remove fault by-products (carbon, acids). |

- IEC 60422: "Supervision and maintenance of mineral insulating oils in electrical equipment"

- IEC 60296: "Specification for unused mineral insulating oils for transformers and switchgear"

- IEEE Std 637: "Guide for the reclamation of insulating oil and criteria for its use"

1. Pre-Filtration Analysis: Conduct comprehensive oil testing to define the filtration strategy (e.g., vacuum for high moisture, fine filtration for particles).

2. Equipment Selection:

- Vacuum Oil Purifier: For dehydration and degassing.

- Precision Filtration Cart: For particulate removal.

3. Post-Filtration Verification: Mandatory laboratory testing is required to confirm standards compliance before returning oil to service.

4. Proactive Management: Transformer oil maintenance is dynamic. Implement regular monitoring (typically annual) even after successful filtration.

Conclusion: Transformer oil filtration standards are not static. They form a dynamic management system based on voltage class, operating conditions, and maintenance objectives. The ultimate goal is to restore oil properties to a level that ensures safe and reliable transformer operation for both insulation and cooling functions.

Root Causes of Loss of Control in Vacuum Oil Purification Systems

How Industrial Oil Filters Remove Water and Impurities: A Comparison of Technical Principles

How to Choose the Right Industrial Oil Purifier: A Comprehensive Buyer’s Guide

How to Choose the Right Oil Purifier for Different Oil Types?

Double-Stage Vacuum Pumping: The Complete Guide to Transformer Maintenance