E-mail seo@sino-purification.com

Time:2025-06-23 16:10:36 Reading volume:

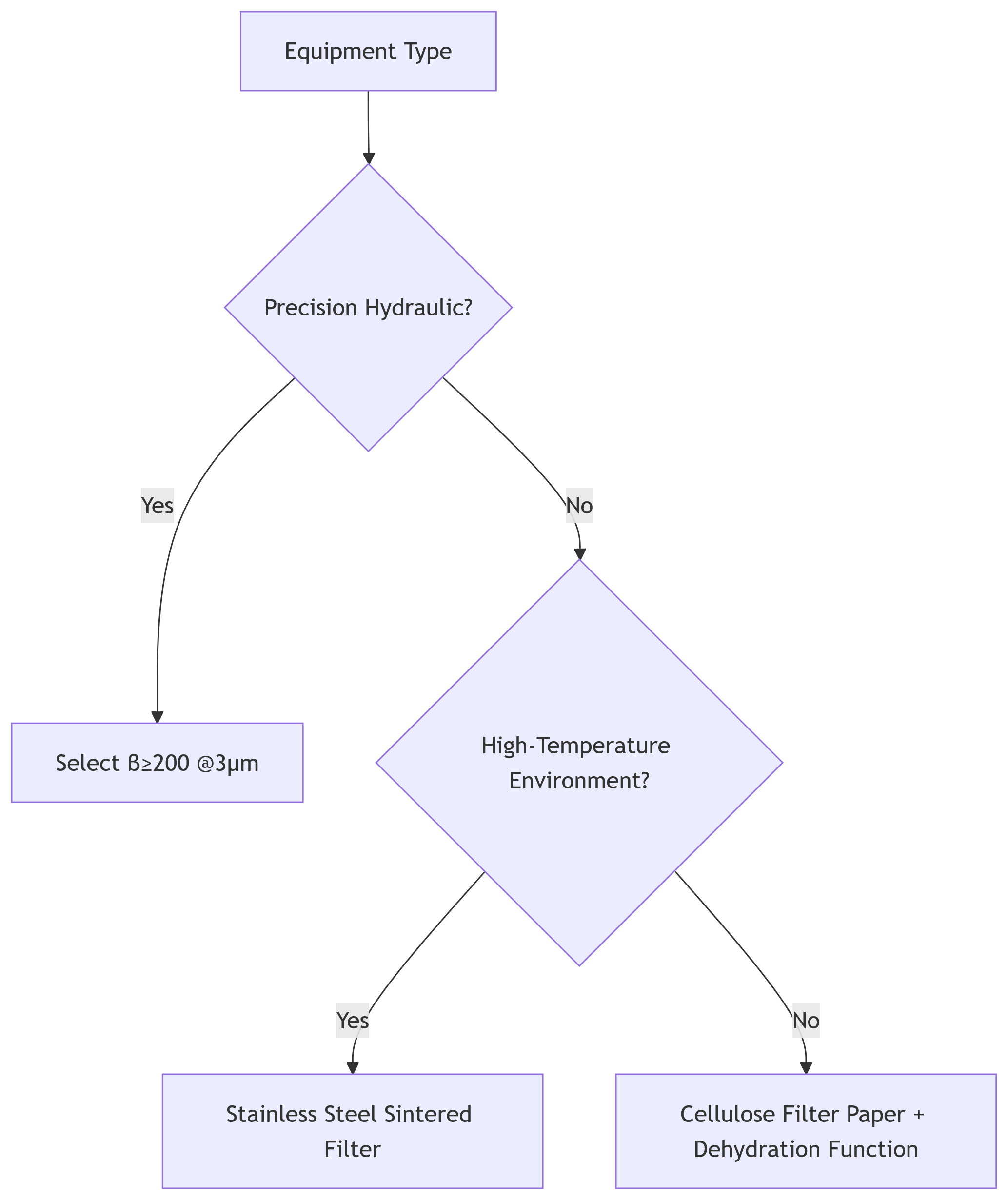

The lubricating oil purifier grade standard is a key indicator for measuring filtration accuracy, and the cleanliness requirements for different application scenarios vary significantly. The following is a globally used classification system and selection guide:

1. ISO 4406 (hydraulic oil cleanliness standard)

| Grade code | Number of particles per milliliter (≥4μm/6μm/14μm) | Applicable scenarios |

|--------------|-----------------------------------|---------------------------|

| 13/11/8 | ≤80/≤20/≤2.5 | Aviation hydraulic system, precision servo valve |

| 16/14/12 | ≤3200/≤640/≤160 | Industrial gearbox, general hydraulic station |

| 21/19/17 | ≤40000/≤10000/≤2500 | Mining machinery, ship heavy-duty equipment |

2. SAE AS4059 (aerospace standard)

- Class 3: ≤5μm particles account for 99% (turbine engine lubricating oil)

- Class 6: ≤15μm particles account for 98% (landing gear hydraulic oil)

3. NAS 1638 (North American aerospace standard)

| Grade | 5-15μm particle count/mL | 15-25μm particle count/mL |

|----------|---------------------|---------------------|

| NAS 0 | ≤125 | ≤10 |

| NAS 6 | ≤20,000 | ≤1,000 |

| Filtration accuracy | Filter material type | Typical β value | Interception efficiency |

|--------------|-----------------------|-------------|-------------------|

| 1-5μm | Glass fiber composite filter paper | β≥200 | 99.5% @3μm |

| 10-25μm | Sintered stainless steel | β≥75 | 98.7% @15μm |

| 30-50μm | Cellulose filter paper | β≥20 | 95% @40μm |

1. Turbine oil system (GB/T 14541)

- New oil injection standard: NAS Grade 6 (ISO 16/14/12)

- Running oil: NAS Grade 8 (ISO 18/16/14)

2. Hydraulic system (ISO 11171)

- Servo valve system: ≤5μm (β≥200)

- Plunger pump system: ≤10μm (β≥100)

3. Internal combustion engine oil (API 1583)

- Full flow filter: 30-40μm (capture 80% of wear metal chips)

- Bypass filter: 3-5μm (remove soot particles)

1. β value (filtration ratio)

- Formula: βₓ = upstream particle number/downstream particle number (for a specific particle size x)

- Example: β₅=200 means that the interception efficiency of 5μm particles is 99.5%

2. Multi-pass test (ISO 16889)

- Evaluate the filter life: terminate the test when the pressure difference rises to 2 times the initial value

3. Moisture index

- High-level oil filter needs to control moisture synchronously (ASTM D6304 standard)

- Nanofiber-coated filter material: can capture 0.1μm particles (to meet the cleanliness requirements of electric vehicle gearbox oil)

- Smart filter element: built-in sensor monitors particle concentration in real time (in line with Industry 4.0 standards)

It is recommended to select the oil filter grade according to the equipment OEM manual and perform oil particle counts regularly (according to ISO 11500 detection); excessive filtration may increase system resistance and reduce energy efficiency.