E-mail seo@sino-purification.com

Time:2026-02-04 11:38:47 Reading volume:

Industrial Oil Filters: A Complete Guide to Dehydration and Impurity Removal

In modern industrial maintenance, industrial oil filters are no longer just optional accessories; they are critical systems for extending component life. While most modern units offer both dehydration and impurity removal, the underlying technologies vary significantly in efficiency and application.

This guide examines how high-performance filtration systems address the three primary types of oil contamination, enabling your machinery to operate at optimal performance.

Before selecting a filter, it is essential to identify what you are removing from your system:

Solid Particulates: Metal wear particles, dust, silica, fibers, and carbon soot.

Moisture: Exists in three forms—free water, emulsified water, and dissolved water.

Gases: Dissolved air or entrained bubbles (light hydrocarbons).

Impurity removal is the foundational requirement of any oil purifier, primarily achieved through physical separation:

Precision Media Filtration: Utilizing high-efficiency cartridges (rated at 1 μm, 5 μm, or 10 μm), these filters mechanically intercept solid particles. This is the industry standard for achieving specific ISO 4406 cleanliness codes.

Centrifugal Separation: By utilizing high-speed rotation, the centrifuge forces heavy solids and free water to the outer walls. It is highly effective for high-volume contamination.

Electrostatic Adsorption: This technology uses a high-voltage field to charge sub-micron particles (such as varnish and oxidation by-products) that standard filters cannot catch.

Water is the "silent killer" of lubrication. Depending on the oil type and water state, different technologies are employed:

The Principle: By creating a negative pressure environment inside a vacuum chamber, the boiling point of water is significantly lowered. This allows water (including emulsified and dissolved water) to flash-evaporate at low temperatures without oxidizing the oil.

Key Advantages: Deep dehydration levels, effective degassing, and zero damage to the oil’s chemical additives.

The Principle: Oil passes through coalescing elements that force tiny water droplets to merge into larger drops. These larger drops then sink to the bottom of a collection tank due to density differences.

Best For: Rapidly removing large volumes of free water and breaking down emulsions.

The Principle: Uses hygroscopic materials like molecular sieves or specialty cellulose media to "soak up" moisture.

Best For: Small-scale systems or as a polishing stage for ultra-dry oil requirements.

| Filter Type | Primary Function | Best Use Case |

| Vacuum Oil Purifier | Deep Dehydration + Fine Filtration | Transformer oil, Turbine oil, High-precision Hydraulics |

| Coalescing-Vacuum Hybrid | Demulsification + Rapid Dehydration | Highly contaminated/emulsified industrial lubricants |

| Centrifugal Purifier | Bulk Water & Large Solid Removal | Marine fuel, Heavy engine oils, Pre-treatment |

| Standard Pressure Filter | Particle Removal Only | Non-critical systems with no water ingress issues |

To maximize your ROI, follow these three steps when selecting an oil purification system:

Analyze the Contaminant Profile: If your oil is cloudy, you need Vacuum Dehydration. If it is dark but clear, you likely need Precision Particulate Filtration.

Check Oil Compatibility: High-viscosity gear oils require different flow rates and heating capacities compared to low-viscosity turbine oils.

Define Your Target Cleanliness: Specify your required ISO 4406 or NAS 1638 levels to your supplier to ensure the filter media is appropriately rated.

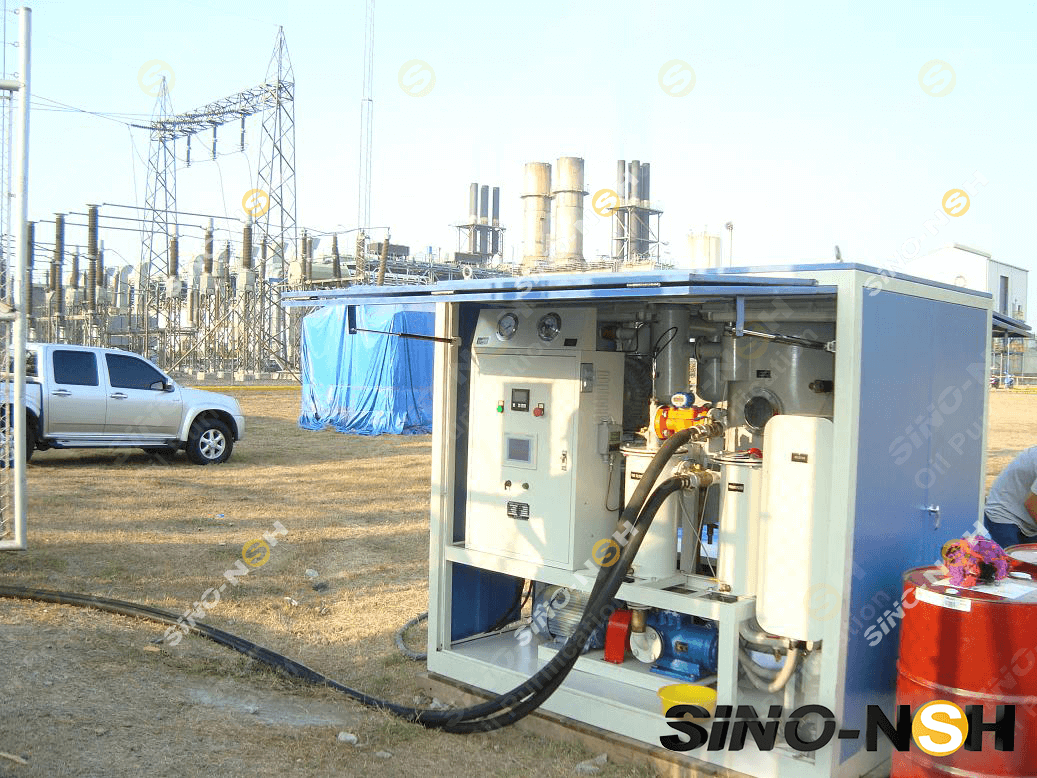

For heavy-duty industrial environments—such as power plants, steel mills, and marine engineering—Coalescing Vacuum Oil Purifiers are the industry benchmark. They provide a comprehensive solution to the "Triple Threat" of water, air, and solid impurities.

How Industrial Oil Filters Remove Water and Impurities: A Comparison of Technical Principles

How to Choose the Right Industrial Oil Purifier: A Comprehensive Buyer’s Guide

How to Choose the Right Oil Purifier for Different Oil Types?

Double-Stage Vacuum Pumping: The Complete Guide to Transformer Maintenance

Lubricating Oil Contamination Risks and Purification Systems for Industrial Equipment